Vortex Flow Meter is one of several types of Flow Measurement where the author will discuss clearly what is vortex flow meter, how does vortex flow meter work, Vortex Flow Meter application and what is the way it is installed? Let’s check out the review below.

Definition of Vortex Flow Meter

Vortex Flow Meter is the most suitable flow measurement device for flow measurement where the introduction of moving parts poses a problem. They are available in industrial, brass or all plastic constructions. Sensitivity to variations in low process conditions and without moving parts has relatively low wear compared to other types of flow meters.

Vortex Flow Meters operate under the vortex release principle, where oscillating vortexes occur when a liquid like water flows through the cliff body (as opposed to streamline). The frequency of the vortex shed depends on the size and shape of the body. It is ideal for applications where low maintenance costs are important. Industrial size vortex gauges are custom-made and require a suitable size for a particular application.

Vortex flow reading technology relies on measuring the number of pulse vortexes produced by a bluff body immersed in a stream stream. Bluff bodies work inside vortex flow meters. As the flow passes through this snapping body, vortices are generated on both sides of the snapping body. The rate of flow can be determined by measuring the amount of vorticity.

History of Vortex Flow Meter

Theodore von Karman, a Hungarian-American physicist, was the first to describe the effect in which a non-current object (also called a bluff body) is placed in a fast-flowing flow path, causing the liquid to alternately separate from the object. on its two downstream sides, and, when the boundary layer becomes detached and rolls back by itself, it forms a vortex (also called a whirlpool or vortex). He also noted that the distance between the vortex was constant and only depended on the size of the rock that formed it.

On the side of the cliff body where the vortex is formed, the fluid speed is higher and the pressure is lower. As the vortex moves downstream, it grows in strength and size, and eventually detaches or detaches. This is followed by the formation of a vortex on the other side of the cliff body. The alternating vortices are placed at the same distance.

Vortex Flow Meter Design

Vortex Flow Meters are usually made of 316 or Hastelloy stainless steel® and include cliff bodies, vortex sensor assemblies, and transmitter electronics, although the latter can also be installed remotely. They are usually available in flange sizes from 1/2 inch to 12 inches. The cost of installing a vortex meter competes with a hole meter in a size under six inches. Wafer body gauges (without flanges) have the lowest cost, while flange gauges are preferred if the processing fluid is dangerous or is at a high temperature.

Bluff bodies (square, rectangle, t shape, trapezoid) and dimensions have been tried to achieve the desired characteristics. Tests have shown that linearity, low Reynolds number limits, and sensitivity to speed profile distortion are only slightly different from the shape of a cliff’s body. In size, the body of the cliff must have a width which is a large enough fraction of the diameter of the pipe so that the entire stream participates in the release. Second, the body of the cliff must have a prominent edge on the upstream face to correct the flow dividing line, regardless of flow rate. Third, the length of the cliff body in the direction of flow must be a certain multiple of the width of the cliff body.

The majority of vortex meters use piezoelectric or capacitance-type sensors to detect pressure oscillations around the cliff body. These detectors respond to pressure oscillations with low voltage output signals that have the same frequency as oscillations. Such sensors are modular, inexpensive, easy to replace, and can operate over a wide range of temperatures —from cryogenic liquids to superheated vapors. Sensors can be placed inside the metered body or outside. Dampened sensors are emphasized directly by fluctuations in vortex pressure and closed in hardened containers to withstand the effects of corrosion and erosion.

External sensors, usually piezoelectric strain gauges, sense the release of the vortex indirectly through the force exerted on the shedder blade. External sensors are preferred in highly erosive/corrosive applications to reduce maintenance costs, while internal sensors provide better range (better low flow sensitivity). They are also less sensitive to pipe vibrations. Electronic homes are usually rated explosion and weather resistant, and contain electronic transmitter modules, termination connections, and optionally flow rate indicators and/or counters.

Vortex Flow Meter Style

Vortex Flow Meter is an intelligent vortex gauge that provides a digital output signal that contains more information than just the flow rate. Microprocessors in a flowmeter can automatically correct insufficient conditions of straight pipes, for the difference between hole diameter and mating pipe, for thermal expansion of cliff body, and for K-factor changes when reynolds number drops below 10,000.

Intelligent transmitters are also equipped with diagnostic subroutines to signal components or other failures. Smart transmitters can start routine testing to identify problems with meters and applications. This on-demand test can also help in ISO 9000 verification.

Some vortex flowmeters can detect mass flow. One such design measures the frequency of the vortex and the strength of the vortex pulse simultaneously. From these readings, the fluid density of the process can be determined and the mass flow calculated in the range of 2%.

Other designs are equipped with multiple sensors to detect not only vortex frequencies, but also the temperature and fluid pressure of the process. Based on that data, it determines the density and rate of mass flow. This meter offers a rate accuracy of 1.25% when measuring liquid mass flow and a 2% rate accuracy for gases and vapors. If knowledge of process pressure and temperature is beneficial for other reasons, these meters provide a convenient and cheaper alternative to installing separate transmitters.

Vortex Flow Meter for Corrosive Liquids

Without moving parts, all electronics are placed in corrosion-resistant containers. Unlike meters that contain metal or moving parts, plastic vortex meters are perfect for aggressive or easily contaminated liquids. Applications range from ultra-pure water to highly corrosive chemicals and slurry.

Industrial Vortex Flow Meters

Measure Vapors, Gases, and Liquids with Low Viscosity. The vortex produced by the flowing fluid puts pressure on the shedder rod in the form of a pulse, and the shedder rod transmits the voltage pulse to an encapsulated piezoelectric sensor.

Vortex Shedding Flow Meter

Operating under the same vortex release measurement principle, this type of vortex flow gauge is suitable for liquids such as viscous, clean, or dirty water that are compatible with brass, PVDF, and FKM. This application is found in most process industries, including rubber, steel, fabrication, manufacturing, refining, paper, chemistry, food, petrochemicals, and electricity. Not suitable for flammable liquids or gases such as air.

Working Principles of Vortex Flow Meter

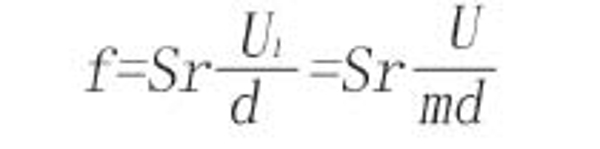

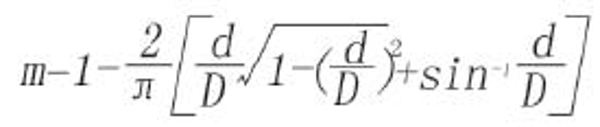

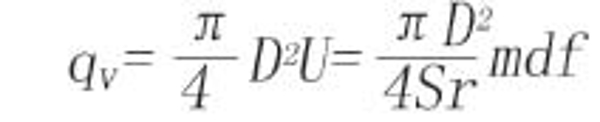

The Working Principle of Vortex Flow Meter and How vortex flow meter works in accordance with the principle of Karman Vortices. When a bluff body is placed vertically inside the pipe, when fluid flows around the bluff body, regular vorticity columns will be generated alternately on each side of the bluff body (shown in Figure.1), these vortexes are known as “Karman Vortices”. Vortex Flow Meter and How vortex flow meter works have a resistance section that releases vortices named “bluff body”. The frequency of vorticity release is related to the speed of the liquid. Stated by the following formula:

Therefore How vortex flow meters work: the frequency of —- from the shedding of Karman Vortices

- Sr —- Strouhal’s number

- U —- average speed in the pipe

- d —- the width of the face of the entry of the cliff body

- m —- the flow-area ratio on either side and measure the area of the pipe section

- U1 —- average speed on two sides of bluff body

Therefore How vortex flow meter works: D —- diameter in the pipe

d —- lebar bluff body inflow face (unit: mm)

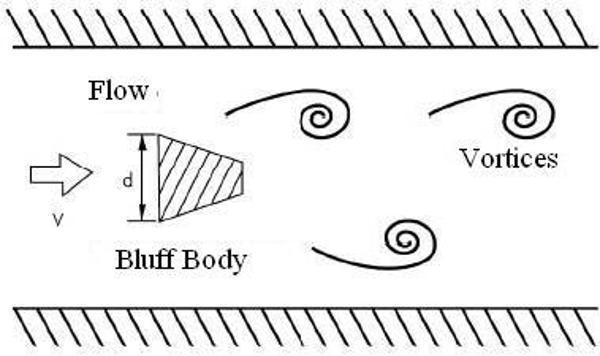

Strouhal numbers are related to the shape of the bluff body and reynolds number (shown in chart 2). From the chart, Sr. is basically constant when reynolds range numbers are ~.

Qformula of volumetric flow momentarily as below:

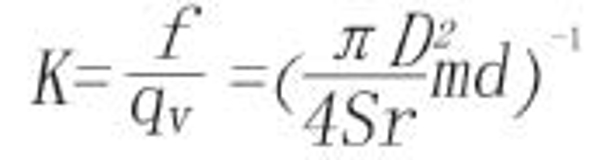

The K meter factor formula as below:

Therefore: q —- volumetric flows through the flow transducer (unit: m3/s)

f —- vorticity frequency (unit: Hz)

k —- the vortex transducer flow factor meter (unit: m)

U —- the average speed in the pipe (unit: m/s)

Chart 2 shows that the volumetric flow rate of the vortex flow meter is proportional to the frequency of vorticity. The K factor meter is only related to the parameters of bluff body geometry, not related to the physical character of fluids and materials.

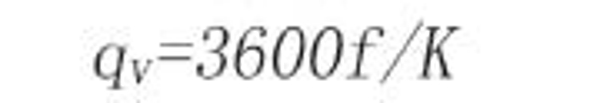

The general formula of vortex flowmeters in projects is as below:

Therefore: f —- releases the karman vortices frequency (unit: Hz)

q —- volumetric flowrate (unit: m3/h)

Introduction to Strouhal Sr. numbers:

Strouhal numbers are a very important factor in the Transducer Vortex Flow. Within a certain range of Reynolds numbers, Strouhal numbers are close to constants. In the range of straight region Sr≈0.17 in the curve (shown in graph 2), the frequency of vorticity release is proportional to the speed, so as long as frequency (f) is detected, velocity (v) will be obtained, and volumetric flowrate will be obtained according to v.

When the fluid flows in a pipe and the Reynolds number is between ~, strouhal number is considered a constant, which can guarantee the accuracy of the measurement range. If outside the reynolds range above, sr will increase when Reynolds numbers decrease or increase, nonlinear will occur. When reynolds numbers are reduced from being, although vortices are shed, the accuracy of the measurement will be reduced, due to nonlinear. So the Reynolds~ number will be referred to as the vortex flow transducer measurement range. That’s How Vortex Flow Meter Works and Vortex Flow Meter Working Principles

Application & Borders Vortex Flow Meter

Vortex Flow Meter applications are not usually recommended for batching or other intermittent flow applications. This is because the dribble flow rate setting of the batching station can fall below the minimum Reynolds number meter limit. The smaller the total batch, the more likely the error is to be generated.

Low pressure (low density) gases do not produce strong enough pressure pulses, especially if the fluid speed is low. Therefore, it is most likely that in such a service the meter range will be poor and the low current will not be measurable. On the other hand, if the range drop is acceptable and the meter is measured correctly for normal flow, the vortex flowmeter can still be considered.

If the process fluid tends to coat or accumulate in the cliff body, as in the application of vortex flow meters on mud and slurry, this will eventually change the K meter factor. Vortex release flow gauges are not recommended for such applications. However, if the dirty liquid has only a moderate amount of non-coating solids, application is likely acceptable. This is demonstrated by a 2-year test on limestone pulp. At the end of the test, the K factor was found to change only 0.3% from the factory’s original calibration, although the cliff body and flow tube were severely damaged and perforated.

When measuring multi-phase flow or vortex flow meter applications (solid particles in a gas or liquid; gas bubbles in a liquid; liquid droplets in a gas), the accuracy of the vortex meter will drop due to the meter’s inability to distinguish between phases. Vortex flow meter application on low-quality wet steam is one such application: the liquid phase should be homogeneously dispersed within the steam, and vertical flow lines should be avoided to prevent slugging. When the pipe is in a horizontal position, the liquid phase tends to flow at the bottom of the pipe, and therefore the inside of the pipe should remain open at the bottom. This can be achieved by installing the cliff body horizontally. The measurement inaccuracies in such applications are about 5% of the actual flow, but with good repetition.

The permanent loss of pressure through the vortex meter is about half of the orifice plate, roughly two head of speed. (Velocity height is defined as V2/g, where V is the flow velocity and g is the gravitational constant in consistent units.) If the pipes and meter are the same size and size, the pressure drop may be only a few psi. However, downsizing (installing a meter smaller than the line size) to increase Reynolds can increase head losses by more than 10 psi. We should also make sure that the contracta vein pressure does not drop under the vapor pressure of the process fluid, as it will cause cavitation. Naturally, if the reverse pressure on the meter is under steam pressure, the process fluid will blink and the meter reading will be meaningless.

Also Read: Gas Vortex Flow Meter

The main advantage of vortex meters is their low sensitivity to variations in process conditions and low wear relative to orifice or turbine meters. Also, the initial and maintenance costs are low. For this reason, they have gained wider acceptance among users.

Installation Recommendations

When installing a vortex flowmeter in an existing process where the flow range is unknown, it is advisable to first make some approximate measurements (using a pitot ultrasonic device or portable clamp). Otherwise, there is no guarantee that the line size vortex gauge will work at all.

Vortex meters require a well-developed and symmetrical flow speed profile, free from any distortion or vortex. This requires the use of a straight up and down pipe to condition the flow. The length of the straight pipe should be equal to the size of the meter and the length should be almost the same as that required for the installation of a hole with a beta ratio of 0.7. Most vortex flowmeter manufacturers recommend a minimum of 30 pipe diameters downstream of the control valve, and 3 to 4 pipe diameters between the meter and the downstream pressure tap. The temperature element should be small and located 5 to 6 diameter downstream.

About half of all vortex meter installations require “shrinking” of large process pipes by concentric reduction and expanders. Even if a flow straightener is installed, some straight pipe (relaxation) will still be required.

Vortex meters can be installed vertically, horizontally, or at any angle, as long as they remain inundated. The meter can remain inundated by attaching it to an upward vertical flow line. When installing a flowmeter in a downward or horizontal flow, the downstream pipe should be kept high. Check valves can be used to keep the pipes full of fluid when there is no flow. Block valves and bypass valves are required if sensor replacement in a particular design requires a flow stoppage and process opening.

Mating flange (on piping schedule 40 or schedule 80 mating) must have the same diameter and hole as the flowmeter. Weld neck flanges are preferred, and reduction flanges should not be used. The inner surface of the mating pipe should be free from the scale of milling, holes, holes, reaming scores and mounds for a distance of 4 upstream diameters and 2 downstream diameter meters. Adjacent meter holes, gaskets, and pipes should be carefully aligned to remove any obstacles or steps.

Excessive pipe vibration can be removed by supporting pipes on both sides of the meter, or by rotating the meter so that the sensor is moved out of the vibration field. Process noise due to chattering valves, steam traps, or pumps can result in high readings or readings that are not zero in zero flow conditions. Most electronic meters make it possible to improve the noise filter settings, but increased noise reduction usually also decreases the sensitivity of the low flow meter. One option is to move the meter to a less noisy part of the process.

Also Read: 9 Flow Meter Recommendations Based on Their Type

Thus the Article About “Vortex Flow Meter: Understanding, Working Principles, and Installation” hopefully can answer all questions of readers and add insight to related articles, hopefully useful. Contact us if interested in this type of flow meter, click here.