The selection of the type of flow meter, based on the method of installation, has an important role in reducing all of the above costs. Therefore, before determining the type of flow meter to buy, it’s a good idea to consider the type and model of the flow meter from the type of installation.

In terms of choosing the type of flow meter that needs to be considered is the optimal value and not the maximum. Referring to the production results, the demands for efficiency, quality stability, cost down and others are prioritized because of the tight competition.

Therefore, when determining the type of flow meter, what needs to be considered is the type of flow meter that has optimal and not maximum benefits. The point is, choose a flow meter that has the accuracy needed and don’t overdo it. Use the flow meter installation type as a consideration for small maintenance costs or approaching free maintenance.

Use a flow meter that costs and installs the lowest possible cost and as short as possible if necessary without having to stop the production process. Next, please proceed with considerations in accordance with the design of the engineering.

In water treatment processes such as those carried out by PDAMs, irrigation and waste treatment processes have experienced many problems when dealing with water flow meters or flow meters. There are 3 important things in deciding the selection of the type of flow meter in applications like this, namely:

- Flow Meter Price

- Installation cost and time

- Maintenance costs and time including calibration

The price of an inline flow meter type flow meter where the installation system by cutting pipes and installing a flange as a pipe flow meter connection medium is very expensive. Because the larger the size of the flow meter, the dimensions and weight are also getting bigger.

The high cost of this type of flow meter is due to the dimensions, weight of the material, transportation costs and others. In terms of installation, it takes a long time and you can imagine for large dimensions like the DNN500 maybe the price of the flange, the cost of cutting the pipe, the long installation time can be very high if calculated in rupiah.

Not to mention during calibration, maintenance and service or if there is a problem with the flow meter, the production will stop or if we want the production to be uninterrupted, there must be a by-pass line when the flow meter must be removed.

To handle this problem, you can use a flow meter with 2 installations, namely:

Flow Meter Insertion Electromagnetic

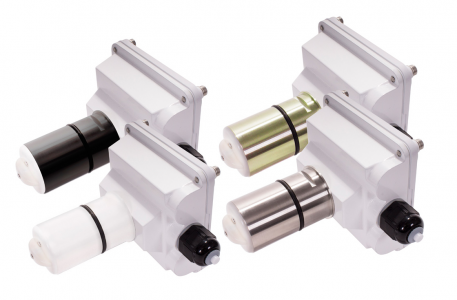

The insertion flow meter is a type of electromagnetic flowmeter whose installation is done by perforating the pipe for the sensor to enter the pipe. Next, a fitting is installed so that it can place the electromagnetic sensor into a fitting that is reinforced with nuts, slotting or pins keys.

The working principle of this type of flowmeter is the same as that of an electromagnetic flowmeter using Farady’s law, where the type of liquid will be detected by the sensor if it has a conductivity above 20 micro Siemens. The type of electromagnetic sensor insertion is usually made of brass or stainless steel material.

Model Insertion Electromagnetic Flow Meter

EX800 Fixed Depth Insertion Magmeter

- Low-flow performance and accuracy superior to any mechanical flow sensor

- No moving parts to wear out

- Dedicated fittings for simplicity

- Retainer clip automatically sets the correct depth

- Meter extends only about 1/8 of pipe diameter, minimizing the potential for clogging with debris

- Simple pulse train output can be used with any SeaMetrics signal processing module or sent directly to a PLC

- Available for pipe sizes 1″ to 12″, in brass, 316 stainless, and PVC

EX90 Series Battery Powered, Insertion Electromagnetic Flow Meter

- Direct replacement for propeller meters

- Easy to install

- Less pipe obstruction

- No moving parts or bearings to replace

- No routine maintenance

- Pulse Output Standard

- 4-year battery life

EX100/200 Adjustable Depth Insertion Magmeter

- Depth adjustable sensors

- EX110 fits any 1-1/2″ pipe fitting (standard saddle, for instance) and adjusts to pipe sizes 3-10″

- EX210 adjusts to pipe sizes 10-48″

- Meter extends only about 1/8 of pipe diameter, minimizing potential for clogging with debris

- Accept Seametrics modules for rate and total indication, 4-20 mA conversion, data logging, and flow switching

- Alternatively, signal can be sent directly to a PLC or other control

- Available in brass or 316 stainless steel

- Immersibility and reverse flow output available

EX150/250 Hot-Tap Adjustable Depth Insertion Magmeter

- Isolation valve allows installation and removal under pressure

- Useful in large water utility pipe and other applications where shutdown is not an option

- EX150 fits pipe from 3″ to 10″

- EX250 fits pipe from 10″ to 48″

- Meter extends only about 1/8 of pipe diameter, minimizing the potential for clogging with debris

- In most applications, the installation tool not necessary due to the small tube diameter

- Available in brass or 316 stainless steel

- Standard valve material is brass, with stainless optional

Flow Meter Clamp-on Ultrasonic

The clamp-on flowmeter is a type of flow meter whose installation method does not cut the pipe or perforate the pipe. This clamp-on flow meter uses a sensor component of the ultrasonic type which is often called an ultrasonic transducer. The working principle of this ultrasonic clamp on flow meter is to measure the fluid flow velocity, using ultrasound so that by calculating the ultrasonic transmitter the flowing volume can be read.

By using ultrasonic sensors can measure the average velocity of the fluid flow in the pipe. The average measurement results are due to the time difference between signal transmission and signal reception with unidirectional or opposite flow.

This clamp on flowmeter has the same installation method and way of working as a portable ultrasonic flow meter. The difference is that this flow meter uses fixed power and is used for long operations or production. As a flowmeter for production, its purpose is to read and store the results of the flow totalizer reading.