Clamp-on Flow Meter WUF 100 CF for PLTU is a flow meter whose way of measuring or calculating the flow speed of a fluid by using ultra sound for flow rate accumulation.

Definition of Ultrasonic Flow Meter

With the known flow speed, it can be calculated flow rate by knowing the area of support of a flow path. Ultrasonic Flow Meter is widely known as a flow meter whose installation system uses a non-contact system where the sensor or transducer does not contact directly with the fluid. Because the way the installation is non contact or clamp on, ultrasonic flow meters are known as portable flow meters.

Likewise for ultrasonic insertion flowmeter installation system the way the installer is to perforate the pipe which is then installed fittings and ultrasonic sensors or transducers are inserted in fittings and pipes that have been in the hole. From the sensor by using cable is forwarded into the ultrasonic transmitter to calculate the velocity and flow rate of fluid in the pipe.

Working Principles of Ultrasonic Flow Meter

Construction of this type of flow meter can be done using upstream and downstream transducers, sensor pipes and reflectors. The working principle of ultrasonic flow meters is, using sound waves to complete the speed of the liquid inside the pipe. There are two conditions inside the pipe as it does not flow and flow. Under the first condition, the frequency of ultrasonic waves is transmitted into the pipe and its indication of a similar fluid. Under the second condition, the frequency of the reflected wave is different due to the Doppler Effect.

Whenever a liquid flows in a pipe quickly, the frequency shift can be increased linearly. The transmitter processes the signal from the wave and its reflection determines the rate of flow. The transit timer sends & receives ultrasonic waves in both directions inside the pipe. Under no-flow conditions, the time it takes to flow between upstream and downstream between transducers is the same.

Under these two flowing conditions, the waves upstream will flow at speeds smaller than downstream waves. As fluids flow faster, the difference between up and down times increases. Upstream & downstream time is processed by the transmitter to determine the flow rate.

Types of Ultrasonic Flow Meter Installations

- Portable Ultrasonic flow meter

- Clamp on fix ultrasonic flow meter

- In Line Ultrasonic Flow Meter

- Insertion Ultrasonic Flow Meter

- Open Channel Ultrasonic Flow Meter

Of the type of ultrasonic flow meter based on the way of installation that is most preferred is the type of installation clamp on because it is very suitable in application to very large pipes or on pipes that they do not want to disturb the production process.

The flowmasonic WUF100 CF clamp-on ultrasonic flow meter series is an ultrasonic flow meter that adopts state-of-the-art, single board technology featuring high precision, high reliability, high performance, low price, etc. which makes it the ultrasonic flow meter of choice by many customers. from all over the world.

The WUF 100 CF Flowmasonic Clamp-on ultrasonic flow meter is available on the market in a variety of sizes, designs, and shapes. It is highly valued for its long functional life.

Features of Clamp-on Flow Meter WUF 100 CF

- Non-invasive clamp-on Technology

- Easy to install

- No pressure drop, moving parts, leakage, or corrosion

- No pipe cutting or process interruption

- Measurement independent of fluid properties

- Wide Bi-directional flow range

- The sensors being a clamp-on type, there’s no pressure loss. The sensors are easily mounted on the surface of the pipe without interrupting the flow for installation or maintenance.

- Advanced intelligent display, computation, and printing(data logger) to suit the user’s diversified requirement. The flow is displayed in all pertinent engineering units. It runs out of regular AC power (110V/220V), built-in battery or DC power.

- Using the most advanced direct-time-measuring method, the meter offers a signal resolution of 0.2ns. In addition, advanced data processing functions ensure the Flowmasonic series WUF100 CF of high linearity.

- Signal outputs including current signal, frequency signal, serial data, switch outputs(1 OCT and 1 relay output). All the outputs displayed on the unit can be transmitted to a PC via RS-232/485 for further processing or storage.

- The Flowmasonic WUF 100CF is designed to measure the fluid velocity of liquid within a closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non-fouling operation and easy installation.

Clamp-on Flow Meter WUF 100 CF Specifications

| Accuracy | : ≤1% |

| Velocity Range | : 0~±10m/s, Bi-directional measurement |

| Pipe Size | : DN32~DN6000mm |

| Temperature | : -30°C~160°C |

| Type of Liquid | : Single liquid than can transmit ultrasound, such as water, seawater, sewage, oil, alcohol, etc. |

| Pipe Material | : Steel, stainless steel, cast iron, copper, PVC, Aluminum, glass steel, etc. A liner is allowed. |

| Signal Output | : 1 way 4-20mA output1 way OCT pulse output

1-way Relay output |

| Signal output | : 3 way 4-20mA input, achieve to heat measurement by connecting PT100 platinum resistor. |

| Interface | : RS485, support MODBUS |

| Data Storage | : SD card regularly store the pre-set result(optional) |

| Power Supply | : DC8~36V or AC85~264V |

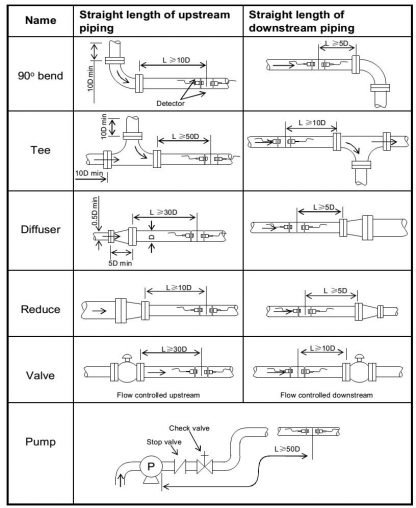

Installation Diagram

The main unit is suitable for installation on the walls, used in most situations without any special requirements. Optional clamp transducer, measurement range of DN32-DN6000mm

Upstream and downstream distance

Working Principle of Transit-Time Technology

For measurement, two ultrasonic pulses are sent through the medium, one in the direction of the flow, and the other against it. Transducers alternately work as transmitters and receivers. The transit time of ultrasonic signals that propagate in the direction of the flow is shorter than the transit time of the signal that propagates against the direction of the flow.

The difference in transit time is measured and allows the determination of the average flow speed on the path of propagation of ultrasonic signals. Profile correction is done to obtain an average flow speed on a cross-section of pipe that is proportional to the flow volume.

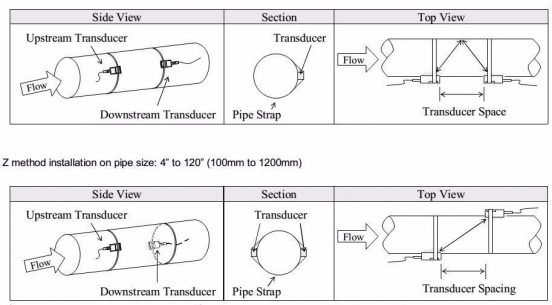

The FLOWMASONIC WUF100 Series transit time clamp flow gauge uses two transducers that serve as ultrasonic transmitters and receivers. The transducer is clamped on the outside of the enclosed pipe at a certain distance from each other.

The Flowmasonic FLOWMASONIC FLOW GAUGE TRANSDUCER WUF100 CF can be installed in the V-method where sound crosses the pipe twice, or the W-method where sound crosses the pipe four times, or in the Z-method where the transducer is mounted on the opposite side of the pipe and the sound crosses the pipe once.

The selection of this installation method depends on the characteristics of the pipe and liquid. The FLOWMASONIC series WUF100 flow meter operates by alternately transmitting and receiving bursts of frequency modulated sound energy between two transducers and measuring the transit time required for sound to move between two transducers. The difference in transit time measured directly and precisely is related to the speed of the liquid in the pipe.

Non-Invasive, Clamp-on Transducers

Because ultrasound propagates in solids, transducers can be attached to pipes. Therefore, the measurement is not invasive, and no pipe cutting is required for the installation of transducers.

With only 3 sets of transducers, pipes ranging from 15mm to 6000mm can be closed, the cost of ownership does not increase along with the increase in pipe size, which is a decisive cost saving factor compared to traditional flow gauges.

Clamp On Ultrasonic Flow Meter Flowmasonic WUF 620 CF Series