Coriolis Mass Flow Meter is one of several types of Flow Measurement and the most accurate type of flow measurement, before we discuss it further, it’s good for readers to understand first from general things such as, definition, how it works, and the benefits of the Coriolis mass flow meter, come on let’s discuss.

Definition of Coriolis Mass Flow Meter

Coriolis Mass Flow Meter is a type of flow meter which is mainly used in mass-related processes such as chemical reactions, heat transfer, etc. In all these processes, accurate flow measurement is a prerequisite.

There are many types of mass flow meters available in the industry. However, the most widely used type is the Coriolis meter. Another type available is the thermal type mass flow meter.

The Coriolis meter works on the Coriolis Effect, hence the name. Coriolis meters are considered true mass meters as they tend to measure mass flow rates directly while other flow meter technologies measure volumetric flow.

Since the mass does not change, no adjustments are needed for various fluid characteristics. Therefore, the Coriolis meter operates in a linear fashion. This type of meter comes in a variety of designs.

The Most Common Unit Types are Coriolis Mass Flow Meters :

- U .-shaped flow tube

- sensor assembly

- electronic unit

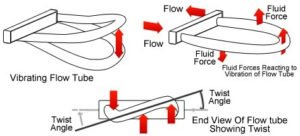

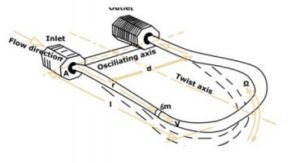

In this meter unit, the liquid passes through a U-shaped tube which vibrates in angular harmonic oscillations. The Coriolis force will then damage the tube and a vibration component is then added to the already oscillating tube. This additional vibration element produces a phase shift or rotation in some parts of the tube. A Coriolis meter is shown in the figure below:

The resulting phase shift which is directly proportional to the mass flow rate of the liquid is measured with the help of a sensor. This measured information is then transferred to an electronic unit where it is converted into a voltage proportional to the mass flow rate.

Due to the nature of the construction of the Coriolis mass flow meter sensor which is able to work at extreme cold to hot temperatures and is able to work at high fluid pressures. Therefore, the Coriolis flow meter is very appropriate for use by fluids that have expensive prices where inaccurate accuracy can cause big losses both in terms of cost and product quality.

Coriolis Flow Meter measures fluid mass, not volume so that if there is liquid fluid flowing in a pipe that passes through the Coriolis flow meter, the mass will be calculated so that if there is a mixture of air, the weight of the air detected and calculated by the Coriolis flow meter can be ignored.

The Coriolis flow meter made of stainless steel is very suitable for use in various beverage and chemical industries because in addition to meeting food grade requirements, it also has good resistance to the effects of liquids and corrosive environments.

Working Principle of Coriolis Mass Flow Meter

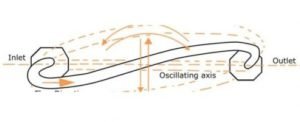

The Coriolis meter has positive and negative Coriolis acceleration into the measurement process, as illustrated in the figure above where the fluid is flowed through two curved tubes. The oscillatory excitation force is directed to the tube through miniature velocity transducers or electric coils, causing vibrations which are measured by magnetic sensors.

The Coriolis flow meter vibrates at a very small amplitude, usually less than 0.1 inch (2.5 mm). This frequency is close to the device’s natural frequency, which is usually around 80 Hz. When there is no flow, the tube vibrates and the sine wave output of each hall-effect transducer is in phase. When flow is initiated, the fluid flowing through the tube thus induces rotation or rotation into the tube due to the acceleration of the Coriolis Effect, which operates in opposite directions on either side of the applied force.

For example, when the flow meter tube moves up during the first cycle, the fluid flowing into the resists meter is forced up and compresses the tube. On the other hand, the liquid flowing out of the resists meter with its vertical downward movement pushes the tube. This action causes the flow meter tube to rotate. As it moves down for two turns of the vibration cycle, the tube rotates in the opposite direction. This twisting produces a phase difference (time lag) between the inlet and outlet sides, and this phase difference is directly affected by the mass passing through the tube.

Notes :

*Note that the amplitude of vibration and rotation is very small compared to the size of the U-shaped tube. The graphic above is intentionally exaggerated for illustration purposes.

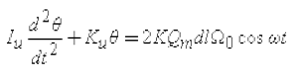

The Coriolis effect on a small liquid section ∂ m is:

![]()

During rotation, the tube exerts an upward resisting force for the fluid, or the fluid pushes the tube down. On the outlet side, the Coriolis force acts in the opposite direction.

For this problem, we assume that the cylinder has a perfect “U” shape, with a cross-sectional area A. The length and width are l and d, respectively. The Coriolis effect, which acts in opposite directions on the inlet and outlet sides, produces a torsional moment, or Tc.

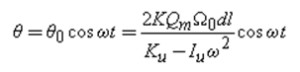

![]()

A K factor can be introduced to compensate for the more common “U” form, where Qm = AV is the flow rate.

![]()

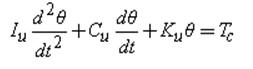

The equation that governs this cycle is:

Where Iu is the inertia of the U-shaped tube, Cu is the damping coefficient, Ku is the stiffness, θ is the angle of rotation, and t is the time.

Knowing that the Coriolis flow meter vibrates in a U-shaped shape to produce rotation, Ω the apparent angular velocity is a function of the vibrating frequency ω.

![]()

Assuming that the Cu damping term is ignored, the twisting equation becomes:

The specific solution (steady-state solution) of the turning angle is:

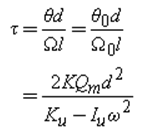

Furthermore, the angular velocity of the U-shaped cylinder is l, and the displacement between these two angles is d/2. Therefore, the time lag between the two angles is:

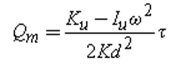

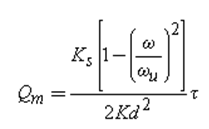

By measuring the time lag Ƭ , the mass flow rate can be obtained:

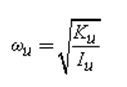

In vibration analysis, it is customary to use the natural frequency as the basis and normalize the frequency term against it. The natural frequency of the U-shaped tube system is:

Notes :

Note that Iu includes the mass of the fluid in the tube.

Then the Mass Flow Meter Becomes:

Until this discussion, we already know and know more about the Coriolis flow meter, starting from its understanding to how the Coriolis meter works.

Main Features of Coriolis Mass Flow Meter

- Coriolis gauges can be applied to a wide range of applications from adhesives and coatings to liquid nitrogen.

- The typical range of curved tube designed Coriolis meters varies from 100:1 to 200:1 while for straight tube meters the range is limited to around 30:1 to 50:1. In addition, the accuracy of straight tube meters is low.

- In the case of the Coriolis meter, no compensation for temperature and pressure variations is required. Also mass measurement is not sensitive to changes in viscosity and density.

- They are especially helpful for handling fluids whose viscosity changes with speed while the temperature and pressure remain constant.

- These are called universal meters, because they are capable enough to measure almost all liquids, liquids and gases. They can measure all fluid flows such as Newtonian, non-Newtonian and moderately solid gases as well.

- They can be used to measure the density of liquids as well.

- There is no Reynolds number limit combined with the Coriolis flow meter.

- They are also unaffected by deformations in the velocity profile.

Advantages of Using Coriolis Flow Meter

- Coriolis flow meters are capable of measuring a wide range of fluids which are often incompatible with other flow measurement devices. The operation of the flow meter is independent of the Reynolds number; therefore, highly virulent fluids can also be measured.

- The Coriolis flow meter can measure the flow rate of Newtonian liquids, all kinds of non-Newtonian liquids and slurries. Compressed gases and cryogenic liquids can also be measured by several designs.

- The Coriolis flow meter provides direct mass flow measurement without the addition of an external measuring instrument. While the volumetric flow rate of a fluid will vary with a change in density, the mass flow rate of a fluid is independent of changes in density.

- The Coriolis flow meter has outstanding accuracy. Base accuracy is usually on the order of 0.2%. In addition, the flow meter is linear throughout its flow range.

- The range of the flow meter is usually on the order of 20:1 or greater. Coriolis flow meters have been successfully applied at flow rates 100 times lower than their full scale flow rates.

- Coriolis flow meters are capable of measuring mass flow rate, volumetric flow rate, fluid density and temperature — all from a single instrument.

- The operation of the flow meter is independent of flow characteristics such as turbulence and profile. Therefore, the upstream and downstream straight flow requirements and flow conditioning are not required. They can also be used in installations that have pulsed flow.

- Coriolis flow meters have no internal obstructions that can be damaged or clogged by slurries or other types of particles in the flow stream. Entrained gas or gas slugs in the liquid will not damage the flow meter. No moving parts, witch will wear out need replacement. This design feature reduces the need for routine maintenance.

- The flow meter can be configured to measure flow in either the forward or reverse direction. In respect of flow there will still be a time or phase difference between the flow detectors, but the relative difference between the two detector signals will be reversed.

- Coriolis flow meter designs are available, allowing for use in sanitary applications, and for the measurement of shear sensitive fluids. Materials are available to allow measurement of corrosive liquids.

Disadvantages of Using Coriolis Mass Flow Meter

- Coriolis flow meters are not available for large pipes. The largest Coriolis flow meters available today have a maximum flow rating of 25,000 lb/min (11,340 kg/min), and are equipped with 6 inch (15 cm) flanges. When larger flow rates are to be measured, two or more flow meters installed in parallel are required.

- Some flow meter designs require very high fluid velocities to achieve large amounts of time or phase difference between flow detector signals. This can result in a very high pressure drop in the flow meter.

- Coriolis flow meters are expensive. However, the cost of a Coriolis meter is often comparable to (or below) the cost of a volumetric meter plus a densitometer used together to determine mass flow rates.

- Coriolis flow meters have difficulty measuring low pressure gas flow rates. Applications with pressures of less than 150 psig are marginal to currently available flow meter designs. Low pressure gases have low densities, and their mass flow rates are usually very low. To produce a mass flow rate sufficient to provide sufficient Coriolis force to be measured, the gas velocity must be very high. This in turn can cause a very high pressure drop on the meter.

[Bonus]Other Benefits of Coriolis Flow Meter

- Better accuracy than most other flow meter technologies.

- Can be used in a variety of fluid conditions (liquid list can be seen in the discussion below)

- Able to measure the flow of hot liquids (example: liquid sulfur) and cold (example: liquid nitrogen)

- Low pressure drop

- Suitable for two-way flow

Thus the article about “Coriolis Mass Flow Meter: Definition, How it Works, and Benefits” hopefully can answer the questions that are in the minds of readers, hopefully it will be useful.