Electromagnetic flow meter or Magnetic Flow Meter and often called magmeter is a type of flow meter that has no moving parts (moving part).

What is Electromagnetic Flow Meter?

This electromagnetic flow meter is ideal when used for measuring inhomogeneous fluid flows, dirty liquids, liquids containing mud or for waste fluids or intake water, raw material water, water from reservoirs or rivers that contain a lot of dirt or garbage (plastic, grass or other), so it is quite suitable for use as a waste flow meter.

This magmeter or electromagnetic flow meter can only be used in water applications that have a certain conductivity, in accordance with the rules required by each electromagnetic flowmeter manufacture.

In general, the magnetic flowmeter does not work on hydrocarbon fluids and distilled water (distilled water / demin water). However, it is ideal for measuring the flow of liquids such as slurries and corrosive materials, such as in chemical processes or beverages or thick water liquids such as soy sauce, sauce, syrup and others. This electromagnetic flow meter is very suitable for use in flow systems that require very low pressure drop.

The working principle of this type of electromagnetic flow meter is based on the law of electromagnetic induction (Faraday’s Law), namely when an electrically conductive fluid passes through an electromagnetic sensor pipe, the fluid will work as a moving conductor that cuts the magnetic field generated by the magnetic coil of the sensor / transducer, so that an induced voltage is generated.

Liquid Conductivity

In general, electromagnetic flow meters can work well if the conductivity of the flow meets the requirements. For the accuracy of the electromagnetic flow meter there is also a minimum flow velocity requirement and a maximum flow rate. Therefore the capacity of the flow meter is not only based on the size of the flow meter which generally follows the dimensions of the pipe

To be more precise, the size or size of the magnetic flow meter refers to the pump capacity or the amount of flow of the fluid in the pipe. This is to maintain the accuracy of the flow meter and at the same time to increase its effectiveness. Because the selection of flow meters with excessive sizes causes high costs.

The Accuracy of Magnetic Flow Meter

Magnetic flow meters have a fairly good accuracy of 0.5% or better for the inline type and 1 = 2% for the insertion type. Meanwhile, from the measurement function because there is no rotating sensor part, it is very suitable for those who do not want excessive pressure drop due to the installation of a flow meter.

Because the position of the sensor or electrode is mounted on the inner wall of the flow tube, which is protected by a liner. Therefore, this flowmeter is suitable for liquids that are dirty, contain garbage, contain solid particles and are even suitable for liquid slurry or mortar for cement and pulp and other liquids.

As long as the liquid being measured has a conductivity above 20 micro Siemens, a magnetic flow meter is suitable. It can even be used for liquids that have extreme characteristics, such as liquid temperatures up to 160 degrees Celsius, have extreme acidity and are corrosive and abrasive, such as sea water to chemical liquids. Likewise for liquids that demand food grade grade, magnetic flow meters are also available with food grade materials, such as stainless steel SUS316 and Teflon as well as ceramic.

Types of Electromagnetic Flow Meter

Electromagnetic flow meters when viewed from the type of installation there are two types, namely:

In Line Model Magnetic Flow Meter

This type of In Line electromagnetic flowmeter is basically a sensor or transducer that has the ability to generate a magnetic field in the form of an electrode. Which is reinforced with a coil (electric coil) around the pipe with the installation of electrodes located opposite on the right and left sides of the pipe body.

This electromagnetic flow meter has a pretty good level of accuracy and can be up to 0.2% for certain models. Named inline flow meter because the installation method is done by cutting the pipe followed by installing a flange or thread. There is also after the pipe is cut the flowmeter is directly welded to the pipe or clamped or clamped as shown below.

Insertion Model Magnetic Flow Meter

Electromagnetic Flow Meter Insertion type is done by inserting an electric coil into the pipe whose flow rate will be measured by installing an electrode at the end. This type is called insertion because the installation method is by perforating the pipe and then fitting it with either a welding fitting or a saddle fitting, then a magnetic sensor is inserted into the fitting.

This type of insertion electromagnetic flow meter is suitable if used for medium to high pipe sizes. Regarding the price of the insertion electromagnetic flow meter, it will be lower if it is applied to pipes with large sizes.

The purpose of installing this type of insertion is usually to shorten the installation time and the installation cost can be cheaper than the inline type, especially for pipe types with large sizes above 10 inches.

The workings of these two types of magnetic flowmeters are the same, namely relying on electric induction as a result of the presence of a current voltage as per Faraday’s law. However, because the working principle is based on electric induction, the magnetic flow meter will be able to work well if the water flow in this flow meter has a conductivity which is usually above 20 micro siemens. Because of that, a magnetic flow meter cannot be used to read the flow of hydro carbon or demin water that has no conductivity or very low conductivity.

Magnetic Flow meter Components

Magnetic Flow Sensor

There are two main parts of a magnetic flow meter, namely the magnetic flow sensor and the magnetic flow transmitter or converter. For the Magnetic flow sensor, there are components in the form of a flow tube, electrode, coil cover and connection in the form of a flange or thread.

The material selection of the magnetic flow sensor must be in accordance with the fluid specifications and installation connections. For electrode materials, you can use the most standard ones, namely SUS316L, Titanium, hast alloy, tantalum, platinum and others. This type of electrode material is very important because an error in choosing the type of electrode material results in a short live time flow meter.

For example, if the liquid being measured is very abrasive because it contains metal and sand, the electrode magnetic flowmeter material from the sus316L material may not be suitable, because it will be damaged quickly by abrasion. Likewise for chemical liquids such as those containing very concentrated sulfate with concentrations above 70% it may be better to use tantalum material which is very well known to be acid-resistant.

The second component of the magnetic flow sensor is a liner, the liner materials can be rubber, Teflon, PTFE, polyurethane and some also use cramic. The selection of this type of liner material is based on the temperature of the liquid, the maximum pressure and the level of abrasiveness of the liquid as well as for the type of liquid which in the process of food, drink and medicine, the type of linet that has a food grade class should be selected.

For materials that need to be heat resistant up to a temperature of 160 degrees Celsius, you should use Teflon or other materials and so on. The main key in material selection is the characteristics and specifications of the fluid and also the piping conditions in the field.

Magnetic Flow Transmitter (Converter)

The second part of the electromagnetic flowmeter is the flow transmitter which has the function of translating the signal from the electrode into a speed count and others that can be displayed in the form of numbers to the display and provide other outputs. This magnetic flow transmitter is usually only divided into integrated or separate forms, the terms in the field are compact/integral or remote/split.

From this magnetic flow transmitter, the flow meter is able to read and detect the flow velocity or velocity, with units of distance per time, water discharge or capacity which is often referred to as flow rate with units of volume per time and can read the volume of liquid that passes through the liquid at a certain time with volumetric units.

Magnetic flow meter accuracy Magnetic flow meters have a fairly good accuracy of 0.5% or better for the inline type and 1 = 2% for the insertion type. Meanwhile, from the measurement function because there is no rotating sensor part, it is very suitable for those who do not want excessive pressure drop due to the installation of a flow meter.

Because the position of the sensor or electrode is mounted on the inner wall of the flow tube, which is protected by a liner. Therefore, this flowmeter should be used for liquids that are dirty, contain garbage, contain solid particles and are even suitable for liquid mud or cement and pulp and other liquids. As long as the measured liquid has a conductivity above 20 micro siemens, a magnetic flow meter is suitable for use. It can even be used for liquids that have extreme characteristics, such as liquid temperatures up to 160 degrees Celsius, have extreme acidity and are corrosive and abrasive, such as sea water to chemical liquids.

Likewise for liquids that demand food grade grade, magnetic flow meters are also available with food grade materials, such as stainless steel SUS316 and Teflon as well as ceramic. This electromagnetic type water flow meter is usually operated with AC power from 90 VAc to 240 VAc, power DC from 12 VDc to 36 VDc or also available with the use of a battery that can last up to 2 years – 5 years.

Likewise, the output is not only a reading on the display but can also provide an analog output of 4-20 mA, Pulse, alarm and RS485 communication. So it is quite complete for those of us who want the results of the flow sensor measurements if it is connected to a control, communication to a computer or remote system such as to GPRS or internet systems.

The Installation of Magnetic Flow Meter

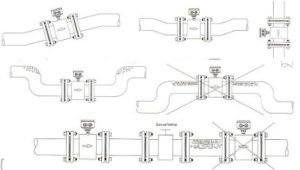

When installing a magnetic flow meter, it is necessary to consider the characteristics of the flow in the pipe at the location of the flowmeter. The purpose of this is that it is expected that the water flow in the flow meter is a laminar flow and there is no back pressure or turbulent flow. Therefore, an adequate installation distance is needed, based on the pipe installation conditions called the upstream and downstream distances.

The following is a basic and general reference for up stream and down stream as a rule for the installation distance of a magnetic flow meter. The flow meter installation distance which consists of up stream and down stream, each magnetic flow meter manufacturer has its own rules, therefore before installing it, you should read the installation instructions carefully, so that we can get the magnetic flowmeter performance according to our expectations.

Advantages and Disadvantages of Electromagnetic Flow Meter

Here we will summarize some of the advantages possessed by Electromagnetic Flow Meters in general and disadvantages when using this type of flow meter, let’s discuss:

Advantages of Electromagnetic Flow Meter

- Electromagnetic flow meters provide quick response to changes in flow.

- Provides a wide linear range.

- The measurement range setting can be optimized.

- Has the ability to measure backflow.

- No additional pressure drop.

- No obstacle is created to flow.

- It is especially suitable for hydraulic solid transportation.

- Unaffected by changes in temperature, density, viscosity, concentration and electrical conductivity.

Disadvantages of Electromagnetic Flow Meter

- Not suitable for low speed.

- It is suitable for liquids having a conductivity greater than 20 micro ohms/cm.

- Gas inclusions cause errors.

Demikian artikel dari “Electromagnetic Flow Meter : Cara Kerja, Jenis, Instalasi, dan Kelebihannya” semoga dapat menjawab semua pertanyaan bagi para pembaca dan dapat menambah wawasan serta mengetahui apa yang belum diketahui, akhir kalimat bukan berarti akhir segalanya, semoga bermanfaat.