Ultrasonic Portable is an inference meter (measuring indirectly) that determines the speed of fluid flow by measuring the transit time of high-frequency sound pulses that cross the flow pipe.

Transit time is the time it takes for sound pulses to cross the pipe in two directions, i.e. in the direction and opposite direction to the direction of the flow.

Ultrasonic flow meter or ultrasonic flow meter is a flow meter that can be used in all applications such as in applications on gases and liquids. Ultrasonic flow meters are some that are used but the most widespread and widely used because they have a non-contact characteristic and can be used by clamp on and a very effective way of use is portable flow meters.

The time difference used to pass from the two directions is proportional to the average flow speed. Because of the measurement of flow based on transit time, this method is also called ultrasonic transit time flow meter.

- Flow meter function

For the method of ultrasonic transit time has the advantage because the way it works based on velocity (flow speed) so it does not depend on the object in the fluid, so ultrasonic type transit time is widely used in custody transfer (product measured has a selling value). In addition, there are also no moving parts (moving objects) or pressure drops (pressure reduction). The resulting accuracy is also good at 0.2%.

Portable Ultrasonic transit time flow meter is suitable for engineers who want to check a system that wants to know the amount or flow rate of a liquid in a pipe.

Usually portable flow meters are used to check the amount of the engine cooling system, lubrication system, pump capacity, and others so that engine dissolution or production quality related to the cooling system can be detected early.

Portable flow meter can also be used to check the performance of the flow meter installed so that the flow meter because the damage can be detected or can also be used to multiply the flow meter installed.

Types of Ultrasonic Flow Meters

Ultrasonic flow meters have several types of installations where this depends on the type of transducer used. As we know there are 3 types of ultrasoonic flow meter transducers, namely:

- In line transducer sensor

- Insertion Transducer sensor

- Clamp On Transducer Sensor

Especially for the type of transducer Clamp On or Clip On Ultrasonic flow meter can be applied to the type of portable flow meter, this is possible because transducer clamp on ultrasonic is quite simple and fast how to use it.

Transducer from ultrasonic clamp on portable flow meter has several sizes depending on the diameter of the pipeline to be measured discharge or flow rate and the total accumulation of fluid flowing at a given time.

Operation of Ultrasonic Portable Flow Meter

Portable ultrasonic flow meter is a flow meter that is identical to the type or definition of ultrasonic flow meter and is widely used for inspection both by QC, Maintenance, Engineer to find out fluid discharge / flow rate.

Here are the steps that must be done in preparing and using portable flow meters:

- Check the completeness of ultrasonic portable flow meter units and make sure there are:

- Main unit Transmitter

- 1 Set Transducer ( 2 ea)

- 1 set Transducer cable ( 2 ea )

- Clamp

- Gel, Coupling compound

- Measuring instruments of length, diameters (ruler, meter or other)

- Charger

- SD card

- Determine the measurement position on the pipe:

- Determine the size of the pipe

- Diameter or circumference

- Pipe thickness

- Linner thickness (if using linner)

- Check the menu M 10 to M 13

- Determine the Type of Pipe Material (Carbon steel, SUS, PVC or laiannya)

- Check the menu M 14 to M 18

- Determine the type of fluid (water, sea water, fuel, oil etc.)

- Check the menu M 20 to 22

- From the size of the pipe that is known to choose the type of transducer in terms of size and working temperature.

- Input the parameters that have been obtained above then look at the transducer distance listed in the transducer distance menu and do not forget to input the type of installation of Transducer (V, Z, N or W)

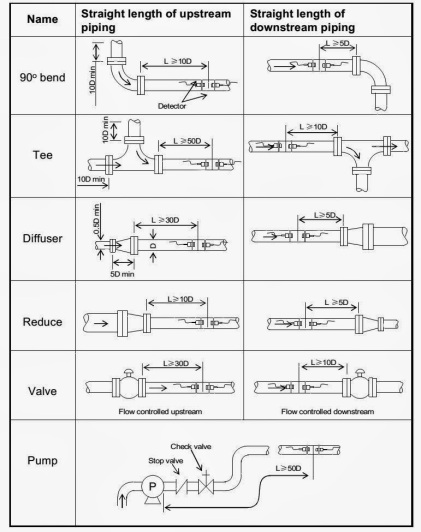

Matode installation flow meter on pipes - Transducer installation

- Mark the place of installation of transducer based on the distance of transducer obtained on the transmitter

- Clean the surface of the pipe from dirt, dust, paint, rust

- Clean the surface of the sensor and give the gel sufficiently and evenly.

- Install Transducer on the surface of the pipe that has been determined

- Clamp Transducer so as not to change its position

- Check once again whether parameters such as pipe diameter, pipe thickness, pipe type, flluid type, transducer type and transducer installation type to ensure the correctness of the parameters.

- Make sure again the units of measurement are good units time can be selected seconds, minutes, hours or days. For volume can be used liters, M3, gallon or others in accordance with their respective wishes.

- Check the tom/tos value whether it meets the requirements specified by manufacture or not 97 – 103

- Turn on the pump or open the valve and wait a while until the fluid in the pipe flows normally.

- Check Q from the flow if Q has qualified the specified where the higher Q and the more stable then the accuracy is better.

- Next, please look at the menu that shows the flow rate and totalizer.

- For applications that you want to store on the sd card please find the menu and do storage.

- For the duration of the check please enter the time menu and so on.

- Next please use other menus in accordance with your purpose using this portable flow meter

Also Read: Portable Flow Meter: Definition, Type, and Function

Thus this article can be delivered hopefully can help and answer all the questions that are in the reader’s mind related to this article, hopefully useful.