The type of calibration flow meter has 2 types, namely, dry and wet calibration, before we discuss more deeply let us first understand the meaning of calibration which is a procedure to maintain the accuracy of a tool. The measuring value of an instrument is compared to the value known or preferred by standard.

Deviation of measurable magnitude from standard value is minimized through the calibration process. Accurate calibration will teach the instrument to produce accurate results with unknown samples. In fact, the purpose of all instruments is to accurately measure unknown samples during normal use.

There are two types of measurements, the first is direct measurement and the other is indirect measurement. Some physical and chemical quantities cannot be measured directly, and these must be measured indirectly. Like a stream that can never be measured directly, it is always measured indirectly. Differential pressure transmitter measures the physical quantity indirectly and then deduces the result to find out the actual physical quantity.

Differential Pressure Transmitters are used to measure flow, density, viscosity and fluid and other levels. How would a single instrument be used to measure so many different physical quantities? In all of these cases, the Differential Pressure Transmitter will measure differential pressure in some form or another and then the results are interpolated to obtain the desired physical quantity. This means that differential pressure transmitters must be calibrated differently to measure a specific physical quantity.

Reset the Differential

Pressure Transmitter

Differential Pressure Transmitter is a 2-wire transmitter. It is a loop-powered device with a 4-20mA current loop protocol as standard. The lower range is 4mA, and the upper range is 20mA. The difference between the lower and upper ranges is called the transmitter range. The application pressure range range requirements must be adjusted to the transmitter range. The transmitter readings are most accurate when using most of its range during measurement. Let’s explain this phenomenon with an example.

Example:

Let’s say, points 4 and 20mA of the DP Transmitter are set to 0 and 100H2O as the original calibration (Please see Figure-1). In this case, the range is 100 10 = 90H2O. There are now some changes in the process and the process pressure requires a minimum of 50 H2O. In this case, the minimum- 0mA is Re-range to 50 H2O. Once this reset is complete, Span will also change to 50 H2O. It is concluded that we need to reset and calibrate the flow meter periodically.

Type of Calibration Dry Differential Pressure Transmitter

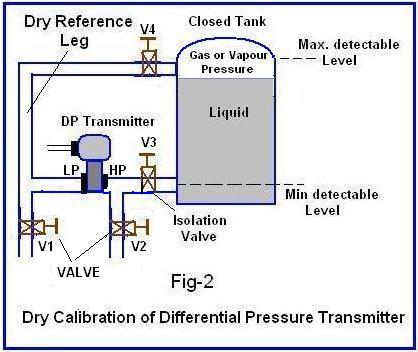

Dry Foot Calibration type or Dry Foot Calibration of Differential Pressure Transmitter is carried out in a closed and pressurized tank. This is a common method and one of the easiest to do. This method is almost similar to open tank level calibration. In a closed tank, the bottommost point is the HP or High Pressure point, and the topmost point is the LP or low pressure point.

The transmitter is installed near the HP or bottom position, and the transmitter’s HP innings is connected to the bottom position of the vessel via the Isolation valve. The transmitter LP innings are connected through the pipe to the very top point. This is shown in Figure 2.

The calibration process is easy. Make both inlet pressures on HP &LP equal to atmospheric pressure by opening both V1 &V2 valves. Calibration of 0mA (Minimum span) is completed. Now, close the V1 & V2, open the isolation valve. Hp’s inflows are subject to the maximum range and calibrate the transmitter to 20mA. Now, open the dry reference foot valve, the LP side will be subject to a minimum range. Reset the transmitter. The dry calibration method is complete.

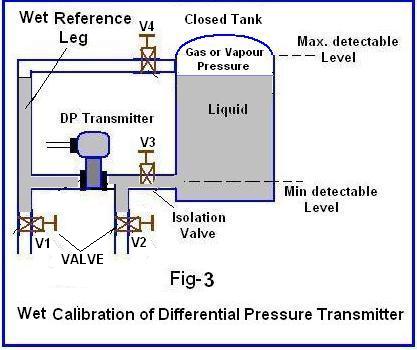

Types of Wet Calibration Differential Pressure Transmitters

Dry calibration only applies if the liquid in the tank is at an ambient temperature. When the liquid is hot or much cooler than the ambient temperature, the liquid vapor or condensate will fill the dry feet. In this condition, dry calibration does not apply. In such situations, wet calibration methods should be adopted.

The LP Leg of the Differential Pressure transmitter set-up should be filled with some buffer solution. Buffer solutions commonly used in industry are diesel, glycol, glycerin or the same liquid from the tank. Now, you should follow the dry foot calibration process, and rearrange it to complete the wet foot calibration process.

We can conclude that a recalibration method is required for all types of Differential Pressure Transmitter applications. Dry foot calibration is only used for height measurement in a closed tank with liquid at ambient temperature. A wet foot calibration method is required for level measurement in a closed tank with hot and very cold liquid.