Ultrasonic Flow Meter is a flow meter that works by measuring or calculating the flow velocity of a fluid by using ultra sound for flow rate accumulation.

What is Ultrasonic Flow Meter?

By knowing the flow velocity, the flow rate can be calculated by knowing the cross-sectional area of a flow path. Understanding Ultrasonic Flow Meters are widely known as flow meters whose installation system uses a non-contact system where the sensor or transducer is not in direct contact with the fluid. Because the installation method is non-contact or clamp-on, the ultrasonic flow meter is known as a portable flow meter.

Likewise for the ultrasonic flowmeter insertion installation system, the installation method is to make a hole in the pipe which is then fitted with a fitting and an ultrasonic sensor or transducer is inserted into the fitting and the pipe that has been perforated. From the sensor using a cable, it is forwarded to the ultrasonic transmitter to calculate the velocity and flow rate of the fluid in the pipe.

Working Principle of Ultrasonic Flow Meter

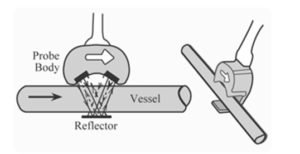

The construction of this type of flow meter can be done using upstream and downstream transducers, sensor pipes and reflectors. The working principle of the ultrasonic flow meter is, it uses sound waves to determine the velocity of the liquid in the pipe. There are two conditions in the pipe such as not flowing and flowing. In the first condition, the ultrasonic wave frequency is transmitted into the pipe & the indication is from a similar fluid. In the second condition, the frequency of the reflected wave is different due to the Doppler Effect.

Whenever the fluid flows in the pipe rapidly, the frequency shift can be increased linearly. The transmitter processes the signal from the wave & its reflection determines the flow rate. The transit timer sends & receives ultrasonic waves in both directions in the pipe. Under no-flow conditions, the time required to flow between upstream & downstream between transducers is the same.

Under these two flowing conditions, the upstream wave will flow at a slower speed than the downstream wave. As the fluid flows faster, the difference between the rise & fall time increases. The upstream & downstream time is processed by the transmitter to determine the flow rate.

Type of Ultrasonic Flow Meter Installation

- Portable Ultrasonic Flow meter

- Clamp on fix ultrasonic Flow meter

- In Line Ultrasonic Flow Meter

- Insertion Ultrasonic Flow Meter

- Open Channel Ultrasonic Flow Meter

Of the types of ultrasonic flow meters, based on the installation method, the most preferred is the clamp-on installation type because it is very suitable to be applied to very large pipes or pipes that they do not want to disrupt the production process.

In Line & Insertion

In accordance with its development, ultrasonic flow meters are also produced with the installation system of In line flow meters and also insertion ultrasonic flow meters. For this type of in-line ultrasonic flow meter, the ultrasonic sensor or transducer is permanently connected to the flow tube which is then transferred to the ultrasonic transmitter or flow computer using a cable. For this type of ultrasonic flow meter, the connection type or installation method is by cutting the pipe which is then installed with a flange or made of thread.

While the fixed clamp on ultrasonic flow meter is widely used to determine the volume or flow rate or to control the flow rate of a closed flow system. Because it is used for continuous flow rate monitoring, the power used usually uses AC or DC electrical power.

Portable Flow Meter

Portable flow meters became famous when the ultrasonic type flow meter was introduced where the method of use and installation is quite easy and fast and can be carried anywhere.

This portable flowmeter uses a clamp on flow meter type where the sensor or often called an ultrasonic transducer is enough to clamp on the outer surface of the pipe, because the installation process does not cut the pipe or perforate the pipe, the installation cost of the clamp on flow meter is very cheap and fast.

For this type of portable flow meter, it is usually equipped with a vaik data logger internally and externally and for power because it is portable it usually uses a battery that can be charged and generally the battery is able to work for a long time above 5 hours.

Clamp On

The clamp on ultrasonic flow meter is a type of flow meter that works using ultra sound and the installation method is simply by clamping it on the surface of the pipe. What is meant by the clamp on installation method is that when performing the installation we do not need to cut the pipe or make holes in the pipe.

By cutting the pipe or perforating the pipe, it will hamper the production process because the water flow must be turned off. In addition, the cost of cutting or perforating pipes followed by welding conection, in the form of flanges or fittings, is not cheap and takes quite a bit of time. Imagine if we had to install a water flow meter on a pipe with a diameter of over 12 inches, we can be sure that the price of flange, gasket, cutting and welding costs can be very expensive.

Because of that, there are many engineers who recommend using a magnetic flow meter type insertion flow meter or a type that tends to be more economical when compared to the in-line type. Because the installation method is enough to make a hole in the pipe followed by welding on the fitting as a place or holder to insert the sensor into the pipe to detect the speed of water flow in the pipe.

This type of clamp on ultrasonic flow meter consists of a sensor or transducer and a flow computer or ultrasonic transmitter. The function of the ultrasonic transducer is as a sensor to detect the velocity of the water flow in the pipe which is then forwarded to the ultrasonic flow transmitter which is then processed by calculating the distance to the time difference from the ultrasonic sound wave so that the velocity of the fluid in the pipe can be obtained.

Advantages of Using Flow Meter Clamp on Ultrasonic

- There are no obstructions in the flow path, so there is no pressure drop.

- There are no moving parts, so there are no worn parts that cause low maintenance costs.

- Multi-sensor models have higher accuracy

- Can be used to measure the flow of corrosive fluids and slurries.

- There are several types of sensors that can measure pipe diameters from size DN15 – DN6000

- If applied to large pipe sizes above 4 inches, it will be more economical than other types of flowmeters.

- The installation cost is very cheap, especially if it is installed on a large pipe

- No need to stop the flow process in the pipeline or no need to turn off the pump

- Can be operated on all types of pipe materials (carbon steel, PVC, HDPE, SUS, etc.) and all types of homogeneous fluids

- Can be operated on wastewater and dirty water with a maximum of 12% solid particles

- Can be mounted on streams with low flow velocity up to 0.03 m/s

- Has a pretty good accuracy of 1% – 2%

- In addition, there is an external data logger using an SD card

- Available analog output 4-20mA, pulse, relay, and communication RS485

- Sensors available with class IP68 (water proof)

In Line Ultrasonic Flow meter

This type which is widely used in the industrial world so far has mostly used the type of flowmeter whose installation method uses a clamp-on system, namely an installation that does not need to cut pipes or make holes in pipes. Therefore, the assumption that most of the engineers are offered with this type is always identified as a clamp on flow meter.

Even though this is the only flow meter that has the characteristics that installation does not need to be done by stopping the flow in the pipe for too long and is identified without having to close the valve or turn off the pump. Even though there are ultrasonic flow meters that use the installation system, they must turn off the pump or close the valve and cut the pipe. This type of installation must cut the pipe and proceed with installing a flange or making threads called InLine as shown below.

Advantages and Disadvantages of Ultrasonic Flow Meter

Here are the advantages and disadvantages of Ultrasonic Flow Meter, let’s see:

Advantage

- It does not block the path of fluid flow.

- These O/P meters differ for the density, viscosity & temperature of the liquid.

- Liquid flow is bidirectional

- The dynamic response of this meter is good.

- The output of this meter is in analog form

- Energy conservation

- It is suitable for large quality flow measurement

- Very useful for customizing and maintaining

- Flexibility is good

- No contact with liquid

- No risk of leakage

- No moving parts, pressure loss

- High accuracy

Disadvantages

- Quite Expensive compared to other mechanical flow meters.

- Too complicated design

- The sensor part of this meter is expensive.

- This meter is complicated compared to other meters, so it requires a specialist to maintain and repair this meter

- Cannot measure cement pipes or corroded concrete.

- Doesn’t work after the pipe contains holes or bubbles in it

- Cannot measure cement/concrete pipes or pipes with such material lining

[Bonus]How to Install Ultrasonic Flow Meter

The most popular ultrasonic flowmeter installation method and information sought by instrumentation equipment users is the clamp-on installation type. There are 2 types of clamp-on flow meters, namely the portable ultrasonic flow meter and the wall-mounting ultrasonic flow meter. For this type of clamp on flow meter, it can be used on pipe sizes from DN15 to DN6000, with several transducer sizes that are adjusted to the pipe diameter. Another advantage of this clamp-on flow meter is that it can be operated on all types of pipe materials and all types of homogeneous fluids.

The installation method of the clamp-on utrasonic flowmeter is very easy and fast, with the first step being to collect pipe and liquid data as variables that must be entered into the ultrasonic flow transmitter. When the data entered corresponds to the actual one, a good ultrasound power will be obtained.

In addition to the pipe diameter, what is usually rather difficult is the pipe thickness data, because the average user does not have a thickness gauge. However, we can enter the thickness of the pipe based on the pipe dimension table which is downloaded via Google. When we need an output from an ultrasonic transmitter that can be input to a PLC or other, don’t forget to set the output parameters, and this is usually based on the flow rate or pulse.

Thus the article “Ultrasonic Flow Meter: Working Principles, Types, and Advantages” Hopefully it can help and answer related articles, hopefully useful.